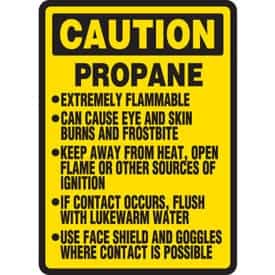

Many articles and blogs give time discussing the safety of operating forklifts, but a very important aspect of safety is the proper way to handle propane. Below are some bulleted points to follow when handling, changing, and filling new and used propane tanks.

- Be sure propane decals are always legible on the LP tank. Each decal will list the manufacture date and also the appropriate retesting date for each tank.

- Relief valves on forklift cylinders must be replaced within 12 years of the cylinder’s manufacture date and every 10 years thereafter.

- Ensure the forklift propane mount has an indicator pin to position the LP tank properly in order for the relief valve to be positioned at the top. This ensures that if over pressurization occurs, it will be released as gas instead of liquid.

- Wearing cotton or cotton-blend clothing will help reduce the chance of reducing a static spark

- Make sure your LP tank is equipped with an overfill prevention device (OPD). An overfilled cylinder doesn’t have enough space left if the liquid expands when exposed to warmer temperatures. This can cause an increase in cylinder pressure and create potentially hazardous conditions.

- Never use a damaged cylinder or a cylinder that has been in a fire. All cylinders should be inspected before they are refilled. The law requires periodic inspection of cylinders and it is against the law to re-fill out-of-date cylinders.

- Never dispose of your propane cylinder by throwing it in the trash. Check to find programs in your area for the collection and disposal of the cylinder.

- The Propane Education & Research Council has some helpful information

If you ever have any questions when handling, changing, or filling propane tanks contact a professional – a local supplier or even your local forklift dealer for safety instructions. Atlantic Forklift Services can train you and your staff on the proper ways to handle propane tanks.