Enhance productivity with reliable forklift accessories

When you incorporate accessories into your forklifts on the job, you get twice the power, with increased efficiency and versatility. Boost the usability of your most useful factory or warehouse machine — the mighty forklift — to transform its abilities from just a standard lift truck. Not only do you save time with more efficient operations,...

Read More

Watch Out!…For this new warehouse safety product

There are many different safety features that come standard on today’s forklifts. Features like steering wheel horn, rear grab bar horn, back up alarms, headlights, rear lights, signal lights, and strobe lights are all typical standard safety features, however there is a newer piece of technology that is proving to be a vital safety feature for...

Read More

Moving Parts: OEM vs Aftermarket

Many organizations consider forklifts to be one of the most vital parts or their operation. The type of parts purchased have a direct impact on the efficiency and profitability of an enterprise. The main questions to ask when ordering parts: Should I use OEM (Original Equipment Manufacturer) forklift parts all the time? What are the performance...

Read More

What does OSHA say about forklift attachments?

Operators must be trained in the proper use of attachments because they alter the performance of the forklift. Attachments affect the truck's performance by changing its center of gravity, visibility, and capacity. These are the federal OSHA regulations and descriptions of forklift attachment installation and use:

Common...

Read More

Cause & Action: Forklift Overheated Engines

During the summer months fork lifts encounter extreme temperature changes. Operating under these conditions can and will affect the cooling systems of any internal combustion engine. As a result, the unit can overheat.

There are several factors that contribute to forklifts overheating, but the most common factors are low coolant, radiator or...

Read More

Maintenance: Routine vs. Preventative

In the material handling industry, many people use the terms ‘preventative’ and ‘routine’ interchangeably when in fact they are worlds apart. Everyone needs to know the difference.

The definition of routine maintenance is simple, small-scale activities (usually requiring only minimal skills or training) associated with regular (daily,...

Read More

Insider Secrets of Buying a Used Forklift

Sometimes buying a new forklift just isn't in the budget. Used forklifts are a clear alternative. Here are a few pointers to point you in the right direction:

Used forklifts should really only be used in a single shift situation, no more than 4-5 hours a day, each day of the week

Know what capacity and height you need

There are...

Read More

Low Cost, Tight Maneuver Doosan Products

With a few new products from Doosan, we'd like to highlight some benefits and features:

These class III material handling trucks are used in conjunction with other sitdown rider units in most industrial applications for their lower cost and tight maneuvering capabilities. There are times when a different driver classification is used - maybe...

Read More

Checklist of Basic Forklift Maintenance

Just like you do spring cleaning for your house, you should be doing it for your material handling equipment, too!

Here are some tips and observations you'll want to read to ensure that you are keeping your equipment maintained and working efficiently.

It is required by OSHA that you have operators utilize a daily check list and provide...

Read More

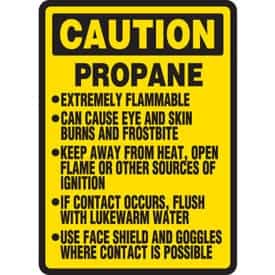

Don’t cause an explosion! Use these propane safety tips.

Many articles and blogs give time discussing the safety of operating forklifts, but a very important aspect of safety is the proper way to handle propane. Below are some bulleted points to follow when handling, changing, and filling new and used propane tanks.

Be sure propane decals are always legible on the LP tank. Each decal will list...

Read More